Not sure you want a electric gate systems? Visit our main page to explore other commercial gate.

We also provide

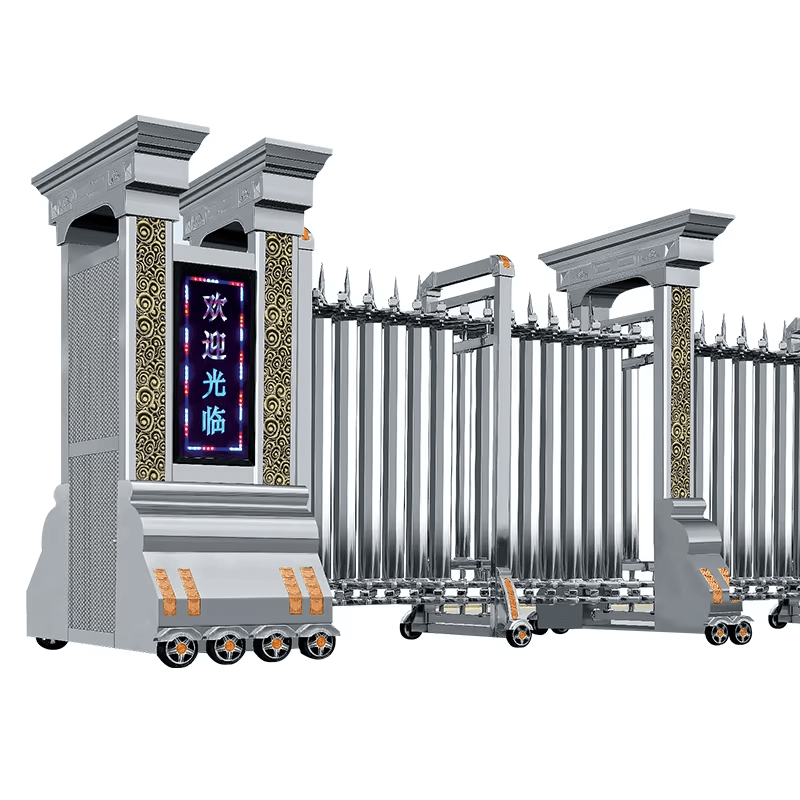

Electric gate systems are essential components for commercial gates, providing both security and convenience. However, like any mechanical system, these gates are susceptible to wear and tear over time. Regular maintenance and an understanding of how electric gate systems work are key to ensuring your gates continue to function safely and effectively. Let’s take a closer look at how electric gate systems operate, common causes of damage, and when it’s time to schedule repairs.

How Do Electric Gate Systems Work?

Electric gate systems are designed to automate the opening and closing of commercial gates, offering ease of access and enhanced security. These gates typically use a motor, which is powered by electricity, to move the gate along its track or pivot it on its hinges. The motor is activated by a signal from a remote control, keypad, or sensor.

When the system is activated, the motor generates torque, allowing the gate to move either horizontally (commercial sliding gates) or vertically (commercial swing gates). The motor is assisted by mechanisms like gears, springs, and sometimes hydraulic arms, which help support the weight and smooth movement of the gate.

A key advantage of electric gate systems is their ability to be customized for various commercial environments, providing controlled access to buildings, warehouses, parking lots, and other secure areas. These systems can be programmed with security features such as timed access, remote monitoring, and integration with security cameras or alarm systems.

Common Causes of Electric Gate System Malfunctions

like all machinery, electric gates experience wear and tear, and several factors can contribute to damage. Here are some of the most common causes of issues with electric gate systems:

-

Normal Wear and Tear: Over time, continuous usage will lead to wear on the system’s motor, gears, and other components. Electric gate systems are often rated for a specific number of cycles, and frequent use in busy commercial environments may result in the need for repair or replacement sooner than expected.

-

Exposure to the Elements

-

Improper Installation or Alignment: A poorly installed electric gate system can place undue strain on the motor and mechanical components. If the gate is misaligned or if there is an issue with the track or hinges, the system will struggle to open and close efficiently, leading to premature wear and possible failure.

-

Inadequate Maintenance: Neglecting regular maintenance of an electric gate system is a major contributor to operational issues. Failing to lubricate moving parts, check for obstructions in the track, or perform electrical checks can result in slow or faulty operation, making repairs necessary sooner than expected.

Signs Your Electric Gate System Needs Repair

Recognizing early signs of trouble with your electric gate system is essential to preventing further damage or safety hazards. Here are some common indicators that your system may need attention:

-

Slow or Jerky Movements: If the gate is not moving smoothly or is taking longer than usual to open or close, it could be a sign of mechanical issues or a malfunctioning motor. In some cases, the gate may be struggling due to improper alignment or a malfunctioning sensor.

-

Unusual Noises: Listen carefully for grinding, squealing, or scraping sounds as the gate operates. These noises are often the result of worn-out parts such as gears, bearings, or rollers that need lubrication or replacement.

-

Electrical Issues: If the gate fails to respond to remote control signals or the keypad, or if it intermittently shuts down without reason, there could be an electrical issue. Damaged wiring, faulty sensors, or issues with the motor can disrupt the system’s functionality and require a professional inspection.

-

Visible Damage: Any visible damage to the gate’s structure, such as bent tracks, broken hinges, or signs of rust on the frame, should be addressed immediately. These issues can impair the gate’s ability to operate and may compromise the security of the property.

Why Professional Service Is Critical for Electric Gate Systems

When dealing with electric gate systems, it’s crucial to call in a professional technician for repairs or maintenance. These systems involve both mechanical and electrical components, making them complex and potentially hazardous to work with. An improperly handled repair can result in injury or further damage to the system.

Experienced technicians are trained to diagnose and repair electric gate systems efficiently and safely. They have the tools and expertise needed to assess the issue, make necessary adjustments, and ensure the system operates at peak performance.

Why Choose a Commercial Gate Shop?

At Commercial Gate Shop, we understand the importance of finding a reliable, experienced partner to bring your vision to life. When you choose Commercial Gate Shop to you with a electric gate system, you can expect:

- Competitive Pricing: We sell directly from the factory, eliminating the middleman and ensuring you get the most competitive price for your commercial telescopic door project.

- Smooth Process: We have many years of experience in designing, manufacturing and installing electric gate system, and have a professional after-sales service team, saving you time and energy.

- Peace of Mind: With Commercial Gate Shop, you can rest assured that your electric gate system will be manufacturing and service by our professional team.

- Exceptional Customer Support: Our prioritise your satisfaction and are committed to providing exceptional support throughout your project, addressing any questions or concerns promptly and professionally.

As you embark on your project contracting journey, let Commercial Gate Shop be your guide. When purchasing our electric gate systems, we ensure a seamless, stress-free experience to support the smooth progression of your project. Contact us today to take the first step towards completing your project with a solid electric gate system.